Permanent Roof Safety Anchors to NZ & Australian Standards

Why are our Anchors better?

Thicker Steel

Multi-Use & Permanent

Long-lasting

Less Deformation

Suitable near the ocean (won’t rust)

Can be painted any colour

Cheaper than scaffolding, and lasts for years

Made in New Zealand

Our RoofSure Safety Anchors are designed and made in New Zealand, to New Zealand & Australian Standards AS/NZS 5532:2013 and AS/NZS 1891.4:2009. Testing was undertaken using a standard medium wind zone residential construction in NZ, using 2.4Kn Mitek Blue Screw Purlin Connections. Anchors must be used with a fall arrest system or static line.

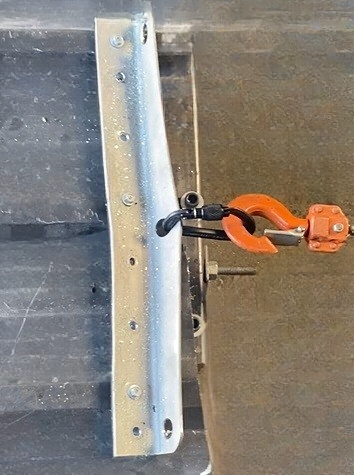

Our Strongest Roof Anchor. Designed for 900mm roof purlin spacings with Vertical Installation and connection into both purlins. Includes 316 Stainless Steel RoofSafe Anchor, EPDM Tape, Hex Screws and Rivets. 1,500Kg load tested with no deformation. Does not include carabiner required for use. All Roof Anchors are to be used with a fall arrest system or static line (not supplied).

Suitable for the following profiles with vertical installation: Corrugate (Custom Orb), Styleline, Veedek, Six Rib, V Rib, LT7, Steel Span, Top Span, Plumbdek, Brownbuilt, DP955.

Shop

Strong and compliant 500mm wide Horizontal fixed RoofSure Safety Anchor. To be installed horizontally across the same purlin. 316 Stainless Steel RoofSafe Anchor, EPDM Tape, Hex Screws and Rivets included. Tested to 1,500Kg for over 3 minutes with minimal deflection. A more compact anchor, or secondary connection point. All Roof Anchors are to be used with a fall arrest system or static line (not supplied).

Suitable for the following profiles: Corrugate (Custom Orb), Styleline, Veedek, Six Rib, V Rib, LT7, Steel Span, Top Span, Plumbdek, Brownbuilt.

Not Suitable for: DP955. Wider Profile required.

Our Strongest Roof Anchor. Designed for 1200mm roof purlin spacings with Vertical Installation and connection into both purlins. Includes 316 Stainless Steel RoofSafe Anchor, EPDM Tape, Hex Screws and Rivets. 1,500Kg load tested with no deformation. Does not include carabiner required for use. All Roof Anchors are to be used with a fall arrest system or static line (not supplied).

Suitable for the following profiles with vertical installation: Corrugate (Custom Orb), Styleline, Veedek, Six Rib, V Rib, LT7, Steel Span, Top Span, Plumbdek, Brownbuilt, DP955.

Safety & Compliance

Our Roof Safety Anchors are designed and made in New Zealand, to New Zealand & Australian Standards AS/NZS 5532:2013 and AS/NZS 1891.4:2009, and 2.4 kN Purlin Fixings at 900 mm x 900 mm centres (9 x fixings).

The installation should only be carried out by a competent person as set out in the AS/NZS 1891.4:2009 Standards. We provide a warranty on product performance of the anchor but not on the structure or the roof sheeting. It is the responsibility of the installer, building designer, or building owner to ensure compliance. If there is any doubt about the structure's adequacy, a structural engineer should be consulted, and PS1, PS3, and PS4 should be issued to prove compliance. We hold no responsibility for inadequate substructure.

The Roof Anchor has been designed and tested to comply with AS/NZS 5532:2013 and AS/NZS 1891.4:2009. These standards have strict restrictions for the use and application of safety harnesses, fall distance limits, and edge safety distances.

Technical & Compliance

Our RoofSure Safety Anchors are designed and made in New Zealand, to New Zealand & Australian Standards AS/NZS 5532:2013 and AS/NZS 1891.4:2009. Testing was undertaken with 2.4Kn Roof Purlins connections (as per NZS3604:2011 for Medium Wind Zone and higher. Anchors must be used with a fall arrest system or static line.

Manufacture: Made in New Zealand by RoofSure NZ

Testing Standard: AS/NZS5532:2013 Table 3.1 & 6.3.1.1 and AS/NZS1891.4:2009 Table 2.1

Ulitmate strength: Free-fall-arrest one Person (15Kn)

Test Duration: 3 minutes at 15Kn loading

Test Result: Pass

Medium Wind Zone: (NZS3504:2011 = 2.4Kn Purlin Fixings).

The anchor was connected to 0.4mm low-rib trapezoidal Colorsteel roofing iron with 12g Tek Screws, and Rivets (supplied with Anchor) into 74x45 Timber Purlins with Medium Wind Zone 2.4Kn Fixings at 900 x 900mm spacings.

Corrosion Resistance: NZS3604:2011 Table 4.1 - Exposed All Zones Type 316 Stainless Steel

Materials: Type 316 Stainless Steel with EPDM Foam Seal spacer.

Fixing: Fixing to be in strict accordance with the supplied fixings. 7x Rivets with Neoprene washers require an 8mm drill bit, the 2x Hex Screws are self-tapping.

Engineer’s Documentation (NZ): PS1, PS3 & PS4

Engineer’s Producer Statement 1 (PS1) available subject to information on sub-structure being reviewed and deemed compliant by Engineer. Engineer's Producer Statement 4 (PS4) available upon receipt of onsite testing information and installers’ Producer Statement 3 (PS3). Engineering & Design Fees are additional.

Technical Installation

VERTICAL INSTALLATION OF ROOF SAFETY ANCHOR

1. Place the anchor & EPDM foam onto the roofing structure parallel with the trapezoidal profile (for Vertical Installation).

2. Ensure each end of the slots are aligned with the Purlins.

3. Fix the 2x end 12G Hexagonal Tek Screws (supplied) into the Purlins.

4. Drill the 7x Rivet holes through the roofing Iron and install the rivets. Ensure tight connection to the Rivets. (Large Rivet Gun required).

5. Install other Roof Safety Anchors via the same method and load test to 750 Kg (7.5Kn). Load testing must be vertical, not horizontal, or damage may occur to the roof. Fill out PS3 Testing Documentation.

6. Once Installed and tested, the Anchor can be used for making connection to a 22Kn Carabiner or Tube Nut Connector. (See Figure 4.4 of AS/NZS 1891)

7. Anchors must be used with a fall arrest system or static line. The Roof Anchor has been designed and tested to comply with AS/NZS 5532:2013 and AS/NZS 1891.4:2009. These standards have strict restrictions for the use and application of safety harnesses, fall distance limits, and edge safety distances.

Technical Health & Safety

New Zealand: Guidelines for Working at Height using Anchor Points: Anyone working at height with an anchor point must comply with the Health and Safety at Work Act 2015 and the WorkSafe NZ guidelines.

Key Compliance Requirements:

PCBUs are required to adhere to AS/NZS 1891 and AS/NZS 5532 standards.

Our Anchor System is guaranteed only if the sub-structure is validated by a Chartered Professional Engineer’s PS1, with all in situ anchors undergoing annual inspection and recertification.

PCBU users must ensure that personnel are adequately trained, holding relevant NZQA unit standards: 17600, 23229, and 15757, along with establishing a comprehensive rescue plan before use.

Building owners must ensure that installation documentation is completed and that annual inspections and maintenance records are accurately kept.

Australia: Guidelines for Working at Height Using Anchor Points:

PCBU’s engaging in work at height with our anchor points must adhere to the national model Work Health and Safety (WHS) Act and Regulations. Key requirements include:

Compliance: Ensure installation aligns with AS/NZS 1891 and AS/NZS 5532 standards.

Installation: All anchor systems should be installed by a "competent person."

Documentation: Best practices recommend that design and installation documents be reviewed and approved by a qualified structural or design engineer.

Recertification: Annual recertification of all anchors must be carried out by a competent person.

Training: The PCBU must confirm that all personnel are adequately trained and possess relevant certifications, such as the nationally recognized "RIIWHS204E Work Safely at Heights" course.

Rescue Plan: Establish a comprehensive rescue plan before usage.

Additionally, building owners are responsible for maintaining and preserving all installation and inspection documentation.

Technical Layout & Use

Total Restraint System, Work Positioning, and Shock Absorber Harness for Safe use.

Total Restraint System

Total restraint systems are strongly recommended and work positioning systems, rather than relying solely on fall arrest systems. A total restraint system prevents a worker from reaching an unprotected edge, thereby eliminating the possibility of a fall. Work positioning systems allow individuals to safely conduct tasks while supported by a tensioned harness, enabling stable, hands-free work. These methods prioritize prevention over mitigation of falls.

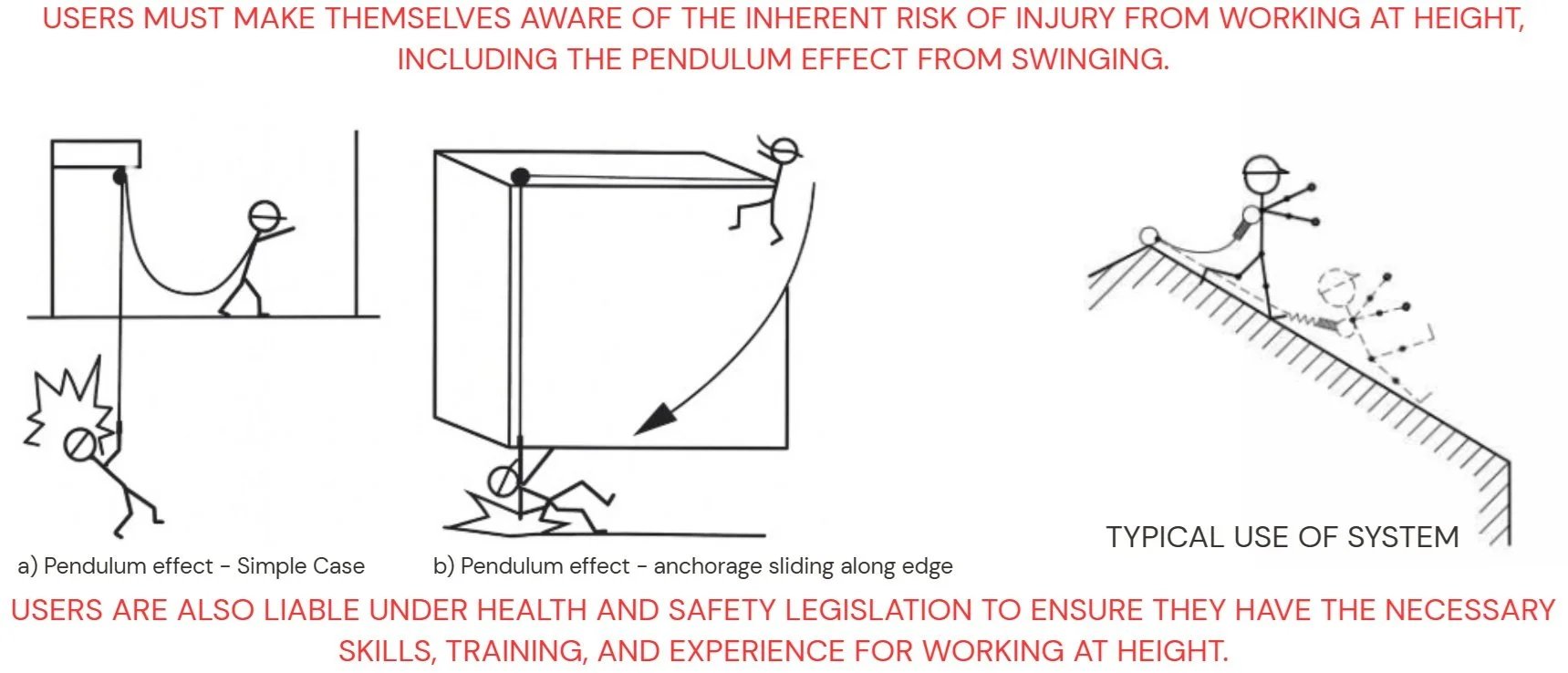

In contrast, a fall arrest system is designed only to protect workers once a fall has already occurred. It is not intended for work positioning, and its use requires a comprehensive rescue plan due to the risk of injury from the pendulum (swing) effect and the potential for post-fall suspension trauma.

Shock Absorber Harness Systems (fall arrest system)

When a fall arrest system is necessary, a shock absorber harness and lanyard should be used to reduce the impact forces exerted on the body during a fall. These systems are designed to minimize the shock load transmitted to the user by deploying (tearing or extending) under force, thereby keeping forces below allowable limits as stipulated in AS/NZS 1891.1.

Shock absorber lanyards must:

Be selected based on the user’s weight, anchor location, and working height.

Be compatible with the anchor system and free from damage, knots, or sharp edges.

Be used only with certified anchorage points, capable of withstanding required load ratings.

Anchor, Line, and System Requirements

Any static line system must be securely anchored and configured to prevent inertia reels or other lanyards from contacting sharp edges.

All fall restraint and fall arrest anchors must be tagged and re-certified annually, in accordance with AS/NZS 1891.4: Industrial fall-arrest systems and devices – Selection, use, and maintenance.

In the event of a fall, work must be planned to ensure the pendulum effect does not result in the worker contacting solid surfaces or the ground.

Harness and lanyard configurations should ensure that any potential free fall is limited to no more than 600 mm.

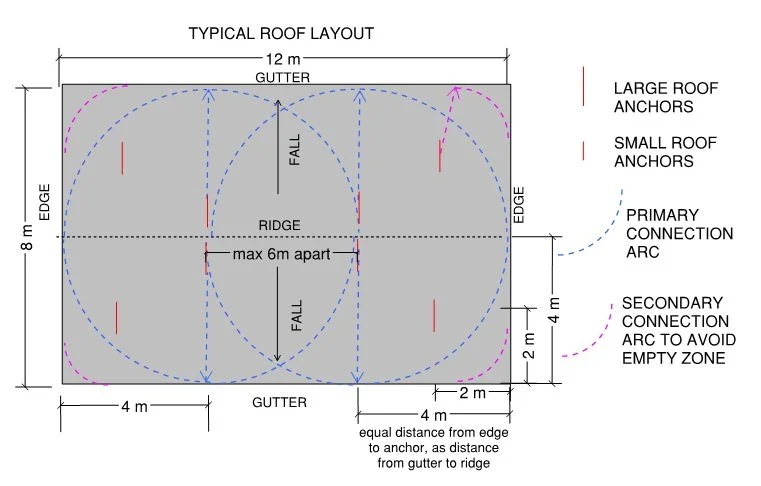

Design & layout of roof anchors is also important, and a roof layout can be provided as an additional service, as part of the PS1 design process.

Primary Roof Anchors should be an equal distance away from the edge, as the length from the ridge to the gutter, to avoid falling off the edge and creating a pendulum fall over the edge.

Secondary Anchors should be installed to access ‘empty’ zones created by the arch of the connection rope/lanyard.

RoofSure anchors are not suitable for a horizontal connecting wire in this configuration, as the load test is down the anchor, not between anchors.

Proof testing of vertical ‘L’ anchors using 12G hex screws into two purlins and multiple rivet connections confirmed the strongest load test results. No deformation or damage to the Anchor or Structure was observed beyond the maximum load duration requirement. These Anchors should not need replacing after 15Kn use, unlike other Anchors that are designed to deform under load. A Carabiner is required to connect to the eyelet. The Anchor is supplied with EPDM foam to provide a separation & waterproofing between the Anchor and Roof Sheeting. The Aluminium Rivets also have a Neoprene washer to provide separation and waterproofing.

About RoofSure & SureProducts

We are solution-based NZ manufacturing and marketing company making products to meet the needs of the NZ & Australian Construction Industry. Our aim is to create innovative products that comply with all relevant standards, are made locally and are competitively priced.

Contact Us

If you would like to know if our system is the right choice for you, or you would like more information, please let us know.